The M113 armored personnel carrier hull is made of aluminum armor alloy, which provides an optimal balance of protection and vehicle weight. The hull structure is load-bearing, meaning all loads from equipment and crew are directly absorbed by the armored hull. Armor thickness varies from 12 to 38 millimeters depending on the area, providing protection against small arms bullets and shrapnel.

The modular design allows quick replacement of damaged sections without complete vehicle disassembly. Parts are connected by welding and bolted connections, which facilitates repairs in field conditions. Hull elements are closely integrated with running gear components and provide mounting for suspension torsion bars and structural elements.

Common damage and repair

Combat operation of the armored personnel carrier leads to various hull damage requiring prompt repair. The most common types of damage include:

- Bullet and shrapnel penetrations in side and frontal parts.

- Ramp damage.

- Hull deformations from mine explosions or projectile hits.

- Cracks in welded seams due to vibrations and dynamic loads.

- Corrosion damage to aluminum alloy in areas where protective coating is compromised.

- Damage to hatches, doors, and their mechanisms from shrapnel and shock waves.

Armor penetration repair requires installation of patches or replacement of damaged sections. Welding of aluminum alloys requires special equipment and qualified specialists. Deformed elements often require complete replacement, as straightening can lead to loss of structural strength.

Main hull parts and their purpose

Spare parts for the M113 hull include a wide range of elements necessary for restoring armored hull integrity.

Hatches and doors provide crew access to the interior space. Opening mechanisms must operate reliably even after exposure to shock waves. Seals prevent water penetration when fording. Equipment brackets are located on interior surfaces, and electrical system spare parts are mounted to special panels.

External hull elements include:

- Towing hook for vehicle evacuation during damage or getting stuck.

- Ramp pump for correct ramp functioning.

- Mounts for additional equipment and spare parts on external surfaces.

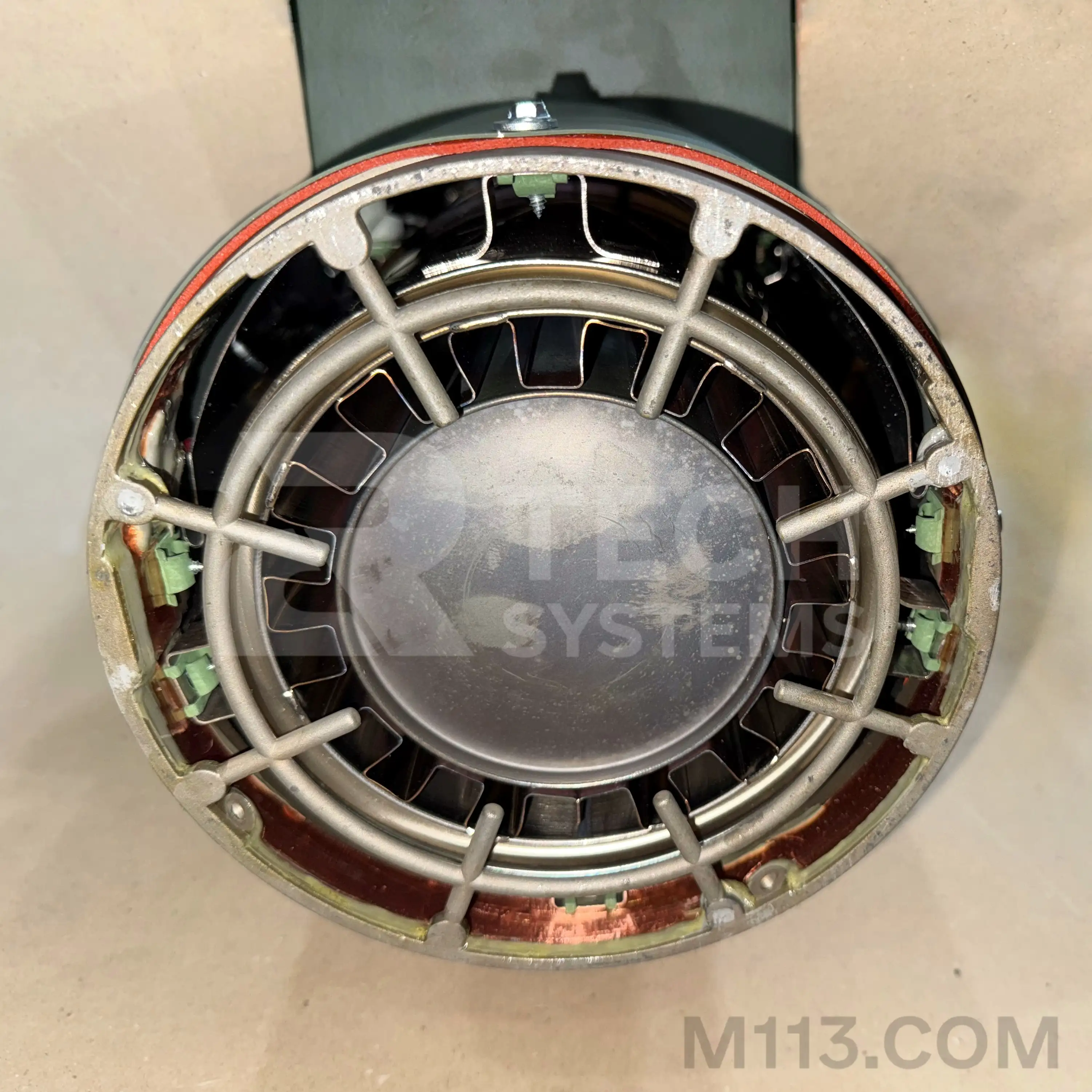

- Air intake protective grilles to prevent foreign object entry.

- Side bumpers to protect sides during maneuvering in confined spaces.

- Antenna and communication equipment mounts on the vehicle roof.

The design provides special openings for access to engine components and vehicle system maintenance.

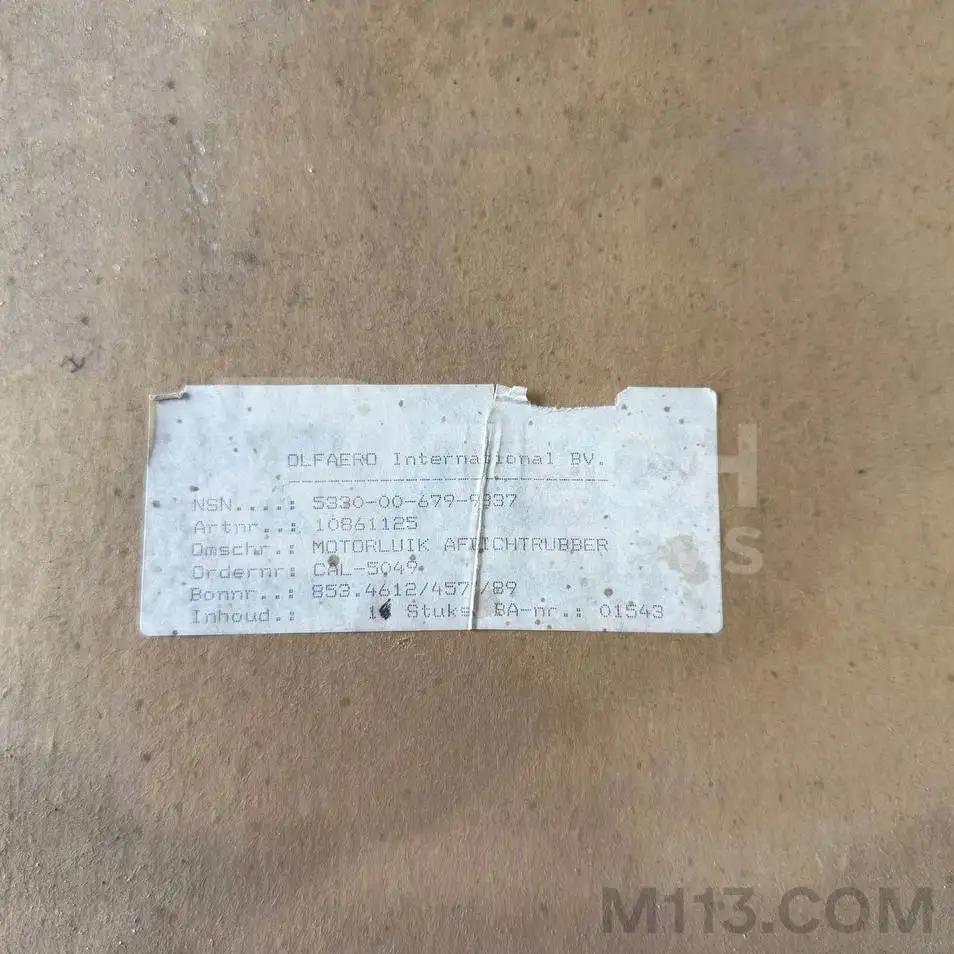

Original and licensed hull spare parts

Repair and maintenance of the armored personnel carrier hull requires the use of quality components that meet military standards. Our range includes a wide range of parts for restoring vehicle functionality: cables, filters, ramp pumps, hooks, and other elements necessary for proper equipment operation.

Licensed spare parts are manufactured by enterprises that have permission to produce components for military equipment. Documentation confirms compliance with technical requirements. When selecting spare parts, it is important to consider not only geometric compatibility, but also material strength and durability. You can purchase certified spare parts through our website.

Hull parts delivery in Ukraine

Supply of large hull parts requires special logistics organization taking into account component dimensions and weight. Our company provides spare parts delivery throughout Ukraine using specialized transport. Packaging is performed using protective materials.

Delivery price is calculated individually depending on dimensions and distance.

You can order spare parts for the M113 hull through the website or by contacting managers. We provide technical support for selecting necessary parts and recommendations on damage repair technology in Ukraine.