The M113 armored personnel carrier engine is a diesel power unit that ensures reliable operation of the vehicle in the most difficult operating conditions. The base modification was equipped with a six-cylinder Detroit Diesel 6V53 diesel engine with a displacement of 5.2 liters and air cooling, producing 215 horsepower. Later versions received more powerful engine variants that provide better dynamics and cross-country capability on difficult terrain.

The M113 engine design is designed for long-term operation with minimal maintenance in field conditions. The V-shaped cylinder arrangement ensures compactness of the power unit and facilitates access to main components for repairs. The direct fuel injection system guarantees economical diesel fuel consumption even under high loads, while turbocharging maintains stable power in mountainous terrain.

Most demanded engine components

During operation of the armored personnel carrier, some engine parts require regular replacement due to natural wear or damage. The most frequently ordered components include:

- Piston groups with rings and pins for restoring compression in cylinders.

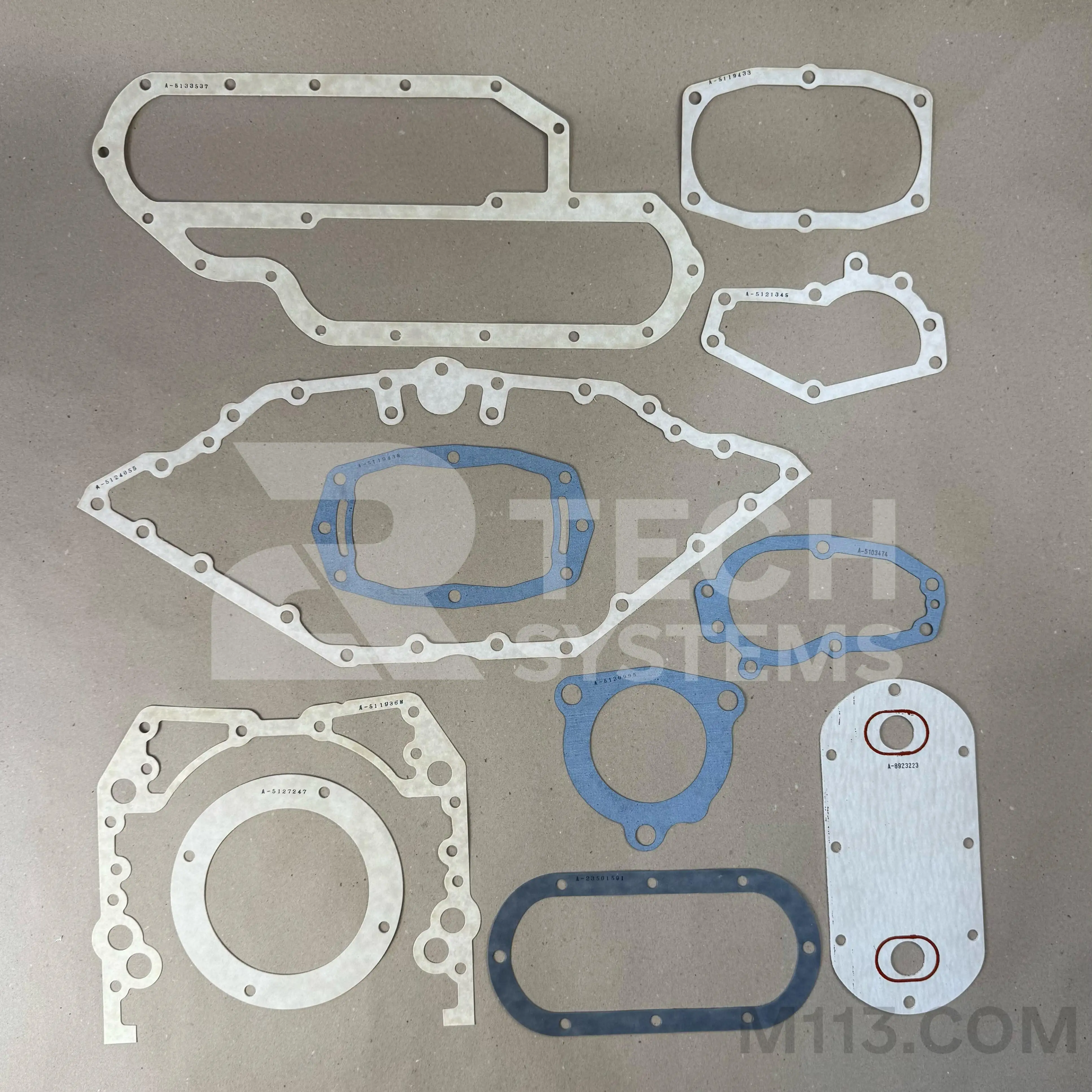

- Gasket and seal kits for sealing joints after disassembly.

- Intake and exhaust valves with guide bushings for the gas distribution mechanism.

- Fuel system injectors to ensure quality diesel fuel atomization.

- Oil and fuel pumps to maintain necessary pressure in the systems.

Filter elements also belong to consumables that require regular replacement. Oil filters protect the engine from abrasive particles, fuel filters clean diesel from contaminants and water. Air filters are especially important when operating in dusty conditions, as they prevent sand and dust from entering the cylinders.

The operation of the engine cooling system is critically important for preventing overheating during intensive operation. Radiators, hoses, thermostats, and pumps ensure optimal temperature conditions for the power unit even in hot weather.

Typical causes of M113 engine failure

One of the common causes of premature wear of engine components is untimely replacement of coarse and fine fuel filters. Fuel injectors become clogged, leading to uneven cylinder operation and power loss.

Insufficient engine oil level or untimely replacement causes critical wear of the piston group, crankshaft bearings, and camshaft. Oil loses its lubricating properties after prolonged operation, especially when operating at elevated temperatures. A clogged oil filter creates a pressure drop in the lubrication system, which can lead to engine oil starvation.

Engine overheating occurs due to cooling system malfunctions or prolonged operation at maximum RPM. Cylinder head deformation from overheating violates combustion chamber tightness and requires complex repairs. Cylinder head gasket damage leads to mixing of coolant with engine oil.

Mechanical damage from projectile hits or explosions can destroy the engine crankcase, damage the piston group, or break the crankshaft. Exhaust system components are also subject to destruction from high temperatures and mechanical impacts, requiring their regular inspection and timely replacement.

Advantages of original engine parts

Original M113 engine components are manufactured taking into account the specific requirements of military equipment. Part materials undergo special heat treatment to ensure high strength and wear resistance in extreme conditions. Manufacturing precision of precision pairs, such as piston-cylinder or plunger-sleeve, guarantees optimal clearances and long service life.

Certified spare parts have complete documentation confirming their compliance with manufacturer technical specifications. Each part undergoes multi-stage quality control, including flaw detection, hardness testing, and geometric parameter verification.

The use of original parts is especially important for critical engine components. Piston groups, valves, injectors, and bearings must meet factory parameters to ensure design service life. Low-quality analogs can lead to repeated breakdowns and additional repair costs.

Procedure for selecting and ordering spare parts

To correctly select engine components, it is necessary to know the exact modification of the armored personnel carrier and the type of installed engine. Part catalog numbers allow identifying the necessary spare parts and avoiding errors when ordering. Our specialists will help determine the necessary components from photographs of damaged parts or from a description of the malfunction.

When ordering spare parts for major engine overhaul, it is recommended to purchase a complete set of parts, including gaskets, seals, and fastening elements. This allows avoiding repeated engine disassembly due to the absence of small components. The price for complete sets is usually more favorable compared to individual purchases.

You can purchase spare parts for the M113 engine through our website or by contacting managers for consultation. You can order urgent delivery to any region of Ukraine for warehouse items. For specific components, we organize supply with minimal waiting times.

Interaction with transmission components also requires attention during engine repair, as worn clutch elements can create additional loads on the power unit.

Recommendations for M113 engine maintenance

Regular engine maintenance extends its service life and prevents serious breakdowns. Main procedures include:

- Engine oil replacement every 200-250 operating hours or according to instructions.

- Checking coolant level before each departure and topping up if necessary.

- Cleaning or replacing the air filter after operation in dusty conditions.

- Checking tension of auxiliary equipment drive belts weekly.

- Draining sediment from fuel filters to remove water and contaminants.

- Checking fuel system tightness to prevent air suction.

If unstable engine operation, increased smoke, or power loss appears, it is necessary to immediately conduct diagnostics. Timely detection of malfunctions allows avoiding expensive major repairs. Compression check in cylinders helps assess the condition of the piston group and valves without engine disassembly.

Storage of spare engine components requires compliance with conditions that prevent corrosion and damage. Parts must be protected from moisture, dust, and direct sunlight. Rubber seals and gaskets are stored in sealed packaging to preserve material elasticity.

Our company provides a full range of spare parts for the M113 armored personnel carrier engine in Ukraine. You can order the necessary components with prompt delivery for quick restoration of equipment combat readiness.